1.0 PURPOSE:

To lay down a procedure for Operation, cleaning and calibration of Scott Volumeter (Density Apparatus).

2.0 SCOPE:

3.0 DEFINITIONS:

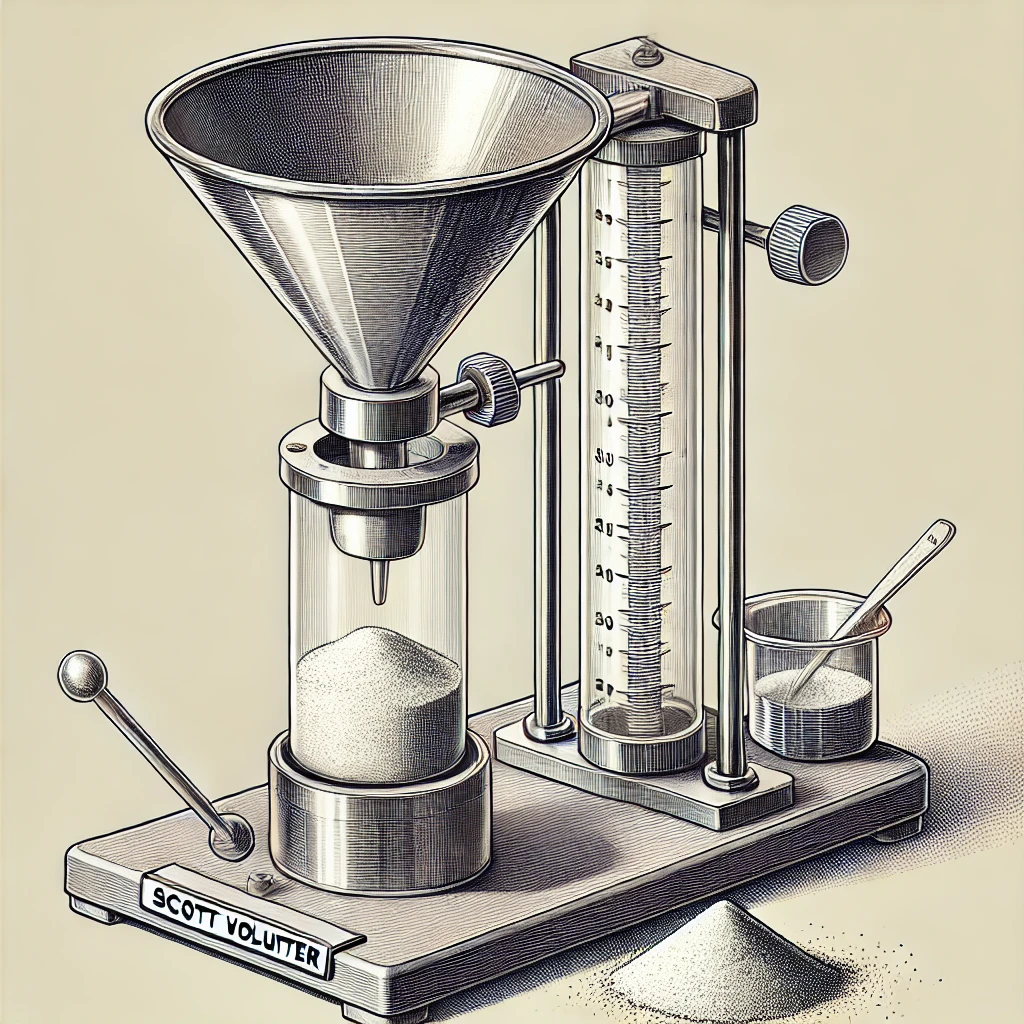

A Scott Volumeter is used to determine the bulk density of powdered or granular substances. It allows material to flow through a funnel into a calibrated container. The bulk density is calculated by dividing the material’s weight by the container’s volume. It is widely used in industries to evaluate flowability and packing properties.

4.0 RESPONSIBILITY:

4.1 Quality control chemist shall be responsible for Operation, cleaning and calibration of Scott Volumeter (Density Apparatus) and maintain the record.

4.2 Head-Quality Control or his designee to ensure compliance.

5.0 PROCEDURE:

5.1 Procedure For General Cleaning:

5.2 Operating Procedure:

5.2.1 Clean the empty receiving cup with tissue paper.

5.2.2 Take weight of the empty receiving cup and note down the weight of the cup as (W1) g.

5.2.3 Place the empty cup in its position.

5.2.4 Slowly pour the powder being tested carefully through the upper funnel until it overflow the receiving cup.

5.2.5 If the powder is not free flowing carefully brush the sample through the top receiving funnel screen without jarring the Density Apparatus.

5.2.6 Note: Jarring of the volumetric could results in packing of the powder in the density cups, thus giving erroneously high values.

5.2.7 Remove the excess powder in the density cup by passing the edge of the spatula blade and in contact with the top of the cup.

5.2.8 Move the spatula smoothly along the top surface of the cup and back again until excess powder has been removed.

Note:

i. Special care being taken to direct the excess powder in to the unfilled area of the cup and the spatula be kept level at all times to prevent packing or pulling out of the powder.

ii. After the leveling operation lightly tap the side of the density cup to settle the powder to avoid spilling while transferring the cup to the balance for weighing.

5.2.9 Clean the outer surface of the measuring cup with tissue paper.

5.2.10 Determine the mass of the powder by weighing the cup with powder and note down the weight (W2) g.

5.2.11 Calculate the weight of the powder is filled in the measuring cup by using the following formula:

5.3 Calibration (Volume Verification):

5.3.1 Clean the measuring cup and dry it, take empty weight of the measuring cup and note down the weight of the measuring cup as (W1) g.

5.3.2 Fill the measuring cup with Purified water and wipe outer surface of the measuring cup, take weight of the cup with water and note down the weight as (W2) g.

5.3.3 Calculate the volume filled in the cup by using the following formula:

5.3.4 Enter the details in the format “Volume verification record” as per Annexure-I.

5.3.5 Acceptance Criteria: Volume of measuring cup should be 25.00 ml + 0.05 ml.

5.3.6 Frequency: Perform the calibration of the measuring cup once in 180 days.

6.0 ABBREVIATIONS:

SOP : Standard Operating Procedure.

ml : Milli liter.

g : Gram

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Volume verification record.