1.0 PURPOSE:

To lay down a procedure for operation and cleaning of Visual inspection board.

2.0 SCOPE:

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Quality control chemist/microbiologist shall be responsible to operation and cleaning of Visual inspection board.

4.2 Head-Quality Control or his designee to ensure compliance.

5.0 PROCEDURE:

5.1 Procedure For General Cleaning:

5.1.1 Ensure the power supply of visual board is switched off, before performing cleaning.

5.1.2 Clean the Surface of visual board with lint free cloth before and after use.

5.2 Operating procedure:

5.2.1 The Visual inspection board will have white background and black back ground.

5.2.2 Switch ON the equipment and ensure that the lights are ON.

5.2.3 Take the test sample, shake it and observe the sample against white back ground for five seconds and similarly by shaking sample observe against black back ground.

5.2.4 Record the observations in respective work sheet of the sample.

5.2.5 Ensure that trained persons are performing the visual inspection.

5.3 Verification of illuminance of light:

5.3.1 Switch “ON” the light source of visual inspection table.

5.3.2 Ensure the cleanliness of LUX meter and its calibration status.

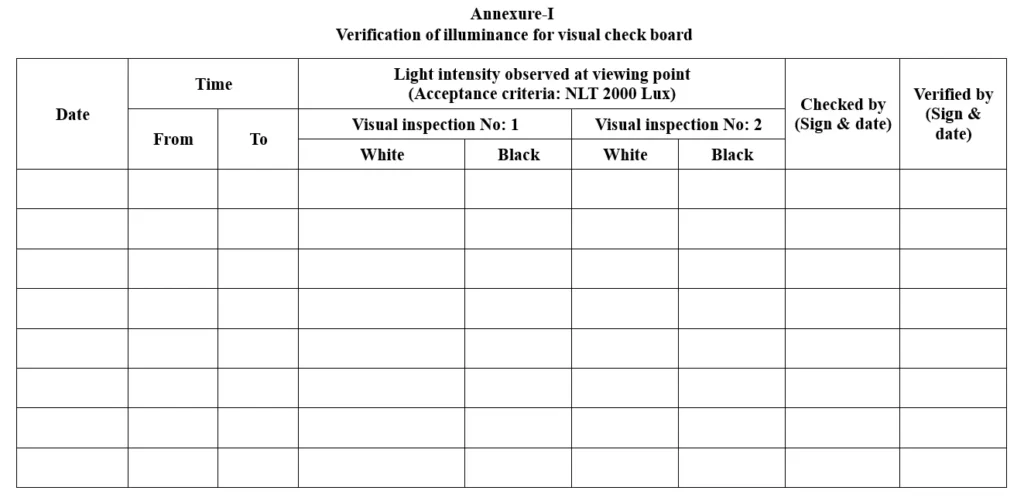

5.3.3 Switch “ON” the Lux meter, take the viewing point at working height and see the light intensity value showing in display of Lux meter. The light intensity at the viewing point should not be less than 2000 Lux. Perform the same procedure for left hand side of inspection table and right side of inspection table in front of black and white background and record the observed reading in Annexure-I.

5.3.4 If the Light intensity value falls below the 2000 Lux do not proceed for visual inspection activity. Change the fluorescent tube of inspection table and again measure the light intensity value after installation and record the same. After getting satisfactory result proceed for further visual inspection activity.

5.3.5 During visual inspection “switch off” the background lights of the area.

5.3.6 Acceptance criteria: The LUX level should not be less than 2000 LUX.

5.4 Frequency: Light intensity shall be checked before start of Visual inspection.

5.5 Pre start up:

5.5.1 Transfer the vials to visual inspection board.

5.5.2 Place the “To be Inspected” vials tray on inspection table.

5.5.3 Update the actual quantity of good vials after completion of visual inspection of same tray.

5.5.4 The Visual inspectors must check 100% of the vials of media fill container for any growth/turbidity.

5.6 Inspection for Liquid Vials:

5.6.1 The operator should not hold more than 2 vials (vial size up to 50 ml) and not more than one vial (vial size more than 50 ml) between the index finger and the thumb at the neck of vial during inspection. Carefully agitate the vial during the visual inspection.

5.6.2 Inspect the vials first in front of white background of inspection table for minimum 5 seconds.

5.6.3 Then inspect the vials in front of black background of inspection table for minimum 5 seconds.

6.0 ABBREVIATIONS:

SOP : Standard Operating Procedure

LUX : Lumens per Square

No. : Meter Number

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Verification of illuminance for visual check board.