1.0 PURPOSE:

2.0 SCOPE:

SOP for operation and cleaning of LAF and RLAF is applicable both in injectable and OSD block at (Company name).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Production / Warehouse operator is responsible to perform the operation and cleaning of LAF’s and RLAF’s.

4.2 Production / Warehouse Officer / Executive is responsible for execution of the procedure.

4.3 Head-Production/Ware house is responsible to ensure the compliance of the procedure.

5.0 PROCEDURE:

5.1 Precaution:

5.1.1 Switch “ON” the LAF/RLAF’s 30 minutes before start of activity.

5.1.2 Verify calibration status of magnehelic gauge mounted on the LAF / RLAF.

5.2 Operation of LAF:

5.2.1 Ensure that the main power is switched “ON”.

5.2.2 Press “Motor Blower” button to “ON” position to turn ON the blower system and hence the air flow starts. Press the same button to OFF position to turn OFF the blower system and hence the air flow stops.

5.2.3 Press “Light” button to “ON” position to turn ON the light. Press the same button to OFF position to turn “OFF” the light.

5.2.4 The reading on magnehelic gauge indicates differential pressure across the HEPA filter.

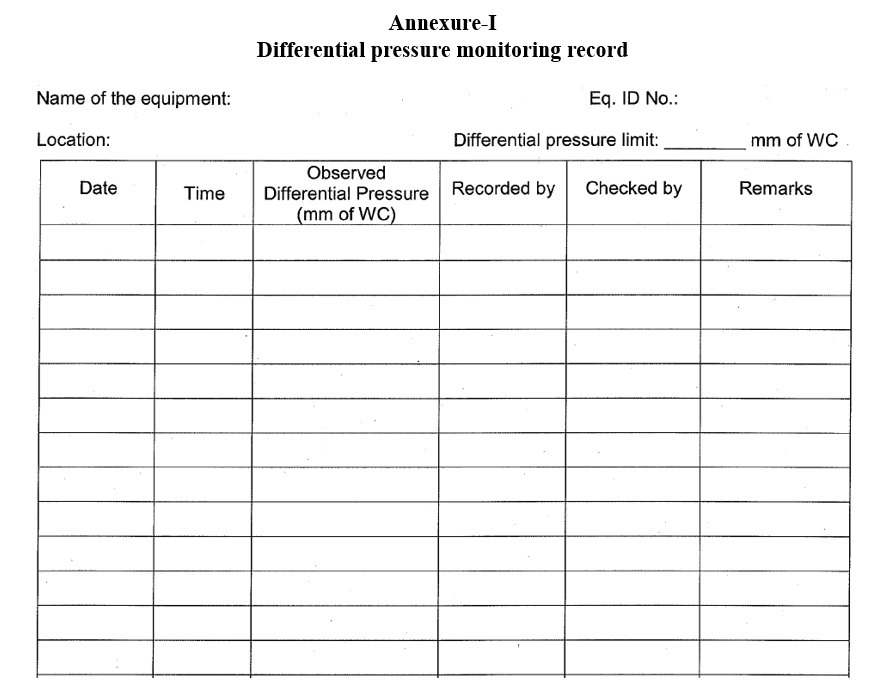

5.2.5 The DP across HEPA filter shall be monitored as per Annexure-I.

5.3 Operation of RLAF:

5.3.1 Ensure that the main power supply is in “ON” condition.

5.3.2 Press “Motor Blower” button to “ON” position to turn ON the blower system and hence the air flow starts. Press the same button to OFF position to turn OFF the blower system and hence the air flow stops.

5.3.3 Press “Light” button to “ON” position to turn ON the light. Press the same button to OFF position to turn “OFF” the light.

5.3.4 The DP across HEPA filter shall be monitored as per Annexure-I.

5.4 Cleaning procedure:

5.4.1 Pre cleaning checks:

5.4.1.1 Ensure that material is not stored under Ceiling mounted LAF / RLAF units before start of cleaning activity.

5.4.1.2 If material is available then transfer it under another Ceiling mounted LAF / RLAF / Mobile trolley / at its designated place and then only start cleaning activity.

5.4.1.3 During cleaning don’t touch the HEFA filter.

5.4.1.4 Ensure that the main power supply of the LAF and RLAF units is OFF before starting cleaning activity.

5.4.2 Cleaning of LAF:

5.4.2.1 Clean the outer surface and PVC curtains of ceiling suspended LAF unit in unidirectional from top to bottom with lint free cloth dipped in scheduled disinfectant solution & hold it for contact time of 10 minutes.

5.4.2.2 Clean the SS table under ceiling suspended LAF unit with lint free cloth dipped in scheduled disinfectant solution & hold it for 10 minutes.

5.4.2.3 Clean the outer surface and PVC curtains of ceiling suspended LAF unit with lint free cloth dipped in WFI / purified water and followed by dry lint free cloth.

5.4.2.4 Clean the SS table under ceiling suspended LAF unit with lint free cloth dipped in WFI / purified water and followed by dry lint free cloth.

5.4.2.5 Wipe the tube light cover, control buttons and glass of magnehelic gauge with dry clean lint free cloth.

5.4.3 Cleaning of RLAF:

5.4.3.1 Clean the inner surface, outer surface and PVC curtains of RLAF unit with lint free cloth dipped in scheduled disinfectant solution & hold it for contact time of 10 minutes.

5.4.3.2 Clean the SS table under RLAF unit with lint free cloth dipped in scheduled disinfectant solution & hold it for 10 minutes.

5.4.3.3 Clean the inner surface, outer surface and PVC curtains of RI.AF unit with lint free cloth dipped in WFI / purified water and followed by dry lint free cloth.

5.4.3.4 Clean the SS table under RLAF unit with lint free cloth dipped in WFI / purified water and followed by dry lint free cloth.

5.4.3.5 Wipe the tube light cover, Control buttons and glass of magnehelic gauge with dry clean lint free cloth

Frequency: Once in a day preferably at the end of activity.

Note:

1. During cleaning in OSD and warehouse use schedule disinfectant and purified water for cleaning.

2. During cleaning in injectable non critical area use schedule disinfectant and WFI for cleaning.

3. During cleaning in injectable critical area use filtered schedule disinfectant, filtered WFI and sterilized lint free cloths for cleaning.

5.5 Monitor and record the differential pressures across HEPA filter of ceiling mounted LAF units and RLAF’s as per Annexure-I.

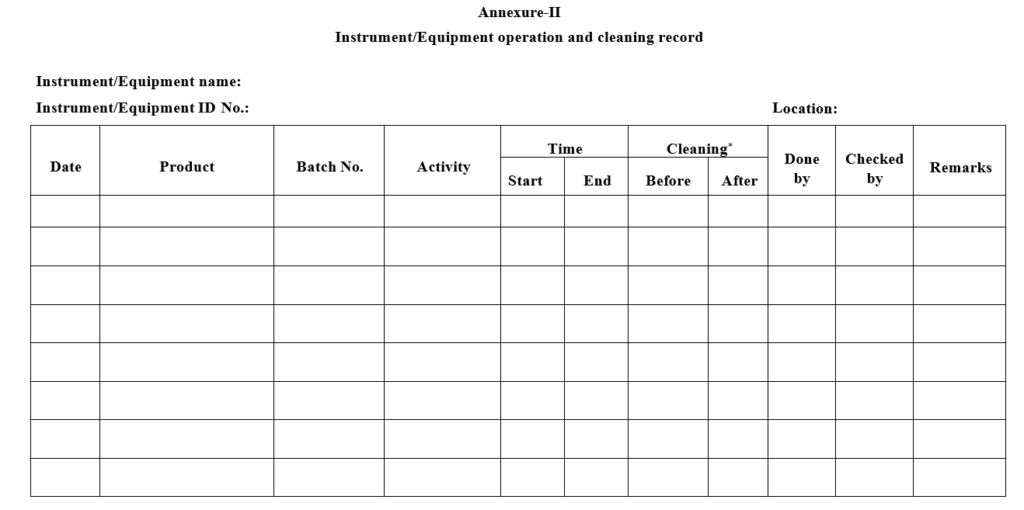

5.6 Record the usage and cleaning activity in Annexure-II.

6.0 ABBREVIATIONS:

SOP : Standard Operating Procedure

No. : Number

HEPA : High Efficiency Particulate Air

LAF : Laminar Air Flow

RLAF : Reverse Laminar Air Flow

Mm : Milli Meter

WC : Water Column

OSD : Oral Solid Dosage

WFI : Water F-or Injection

PVC : Poly Vinyl Chloride

SS : Stainless Steel

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Differential pressure monitoring record.

Annexure-II: Instrument/Equipment operation and cleaning record.

6 thoughts on “SOP for Operation and Cleaning of LAF and RLAF”

Pingback: SOP for Operation And Cleaning of Dynamic Pass Box -

Pingback: Procedure for operation and cleaning of vacuum cleaner -

Pingback: Cleaning and sanitization of waste bins -

Pingback: SOP for Critical Area Practices -

Pingback: SOP for operation and cleaning of static passbox -

Pingback: SOP for dispensing of raw materials -