1.0 PURPOSE:

2.0 SCOPE:

SOP for Operation and Calibration of Bursting Strength Test Apparatus is applicable in Quality Control Department at (Company name).

3.0 REFERENCE:

4.0 DEFINITION:

Calibration: This is an act of checking or adjusting by comparing with known standard for accuracy of the instrument to meet the defined criteria with a specified degree of confidence

5.0 RESPONSIBILITY:

Execution: Officer QC; Checking: Executive QC; Accountability: Head QC.

6.0 FREQUENCY:

Operation: As when required

Calibration: For bursting strength capacity: 6 month.

7.0 PROCEDURE:

7.1 Operation:

7.1.1 Ensure that the instrument is clean and free from dust.

7.1.2 Check the calibration status.

7.1.3 Switch ‘ON’ the ‘MAINS’ of the instrument.

7.1.4 Ensure that the selected gauge displays zero reading.

7.1.5 The 2 different gauges are with different limits as one gauge is with 0 to 42 Kg/cm² (0 to 600 psi) and the other with limits in between 0 to 16 Kg/cm² (0 to 230 psi). Use the gauge as per requirement.

7.1.6 Depending on the type of material to be tested check for the position of the valve in the closed condition for the gauge which is not to be used.

7.1.7 Unscrew the steering to lift the upper movable platform in the upward direction.

7.1.8 Put the test material on the fixed platform and tighten the upper platform by screwing

the steering.

7.1.9 The assembly should be tight enough so as the shipper/carton does not comes out when pulled slightly.

7.1.10 Press the Test Start button continuously without releasing the button until a slight bursting sound is heard and the shipper/carton is ruptured.

7.1.11 Note down the reading displayed on the dial gauge which is the Bursting Strength of the shipper/ carton.

7.1.12 After completion of the test switch off the instrument.

7.1.13 Enter the details into the instrument log sheet as per Annexure-I.

7.2 Calibration:

7.2.1 Calibration for Pressure Gauge:

Bursting strength test apparatus is calibrated by authorized external agency for pressure gauges.

7.2.2 Calibration of bursting strength capacity:

7.2.2.1 Use certified standard Aluminum Foil of 5.6 Kg/cm² and 15.0 Kg/cm² for calibrating of bursting strength capacity.

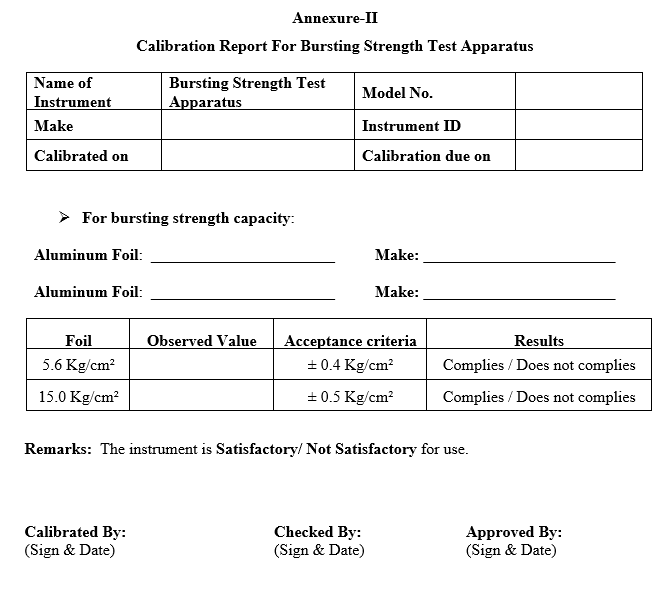

7.2.2.2 Record the calibration details as per Annexure-II.

7.2.2.3 Acceptance criteria: 5.6 Kg/cm² ± 0.4 Kg/cm² and 15.0 Kg/cm² ± 0.5 Kg/cm².

7.3 Precautions:

Clean the instrument with a dry clean cloth before and after use.

8.0 ABBREVIATIONS:

SOP : Standard Operating Procedure.

Psi : Pounds per square inch

9.0 ENCLOSURES:

Annexure-I: Log sheet for bursting strength Test Apparatus

Annexure-II: Calibration Report For Bursting Strength Test Apparatus

2 thoughts on “SOP for Operation and Calibration of Bursting Strength Test Apparatus”

Pingback: Procedure for operation and calibration of micropipettes

Pingback: SOP for operation, cleaning, maintenance and calibration of oven -