1.0 PURPOSE:

To lay down the Procedure for measurement of Air Velocity and air changes per hour.

2.0 SCOPE:

This procedure applies for measurement of Air Velocity and air changes per hour at (Company name).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Engineering personnel shall responsible for measurement of Air Velocity and air changes per hour.

4.2 Engineering head shall responsible to ensure compliance.

5.0 PROCEDURE:

5.1 Frequency:

5.2 Instrument to be used:

5.3 Test procedure:

5.3.1 To measure air flow volume rate through hot wire or Vane type anemometers:

5.3.1.1 Ensure that the respective area HVAC system is switched “ON” prior to start the measurement.

5.3.1.2 Airflow velocity should be measured at a distance of approximately 150 mm to 300 mm from the filter face.

5.3.1.3 Orient the probe at the height of 150 mm to 300mm from the filter face, perpendicular to the velocity flow vector to be measured.

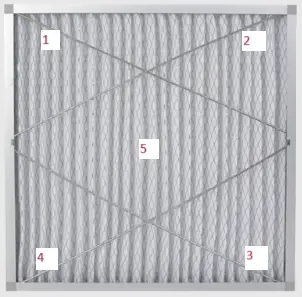

5.3.1.4 Take the readings at the test positions shown in the figure and make sure that all the test positions should be within the unobstructed airflow.

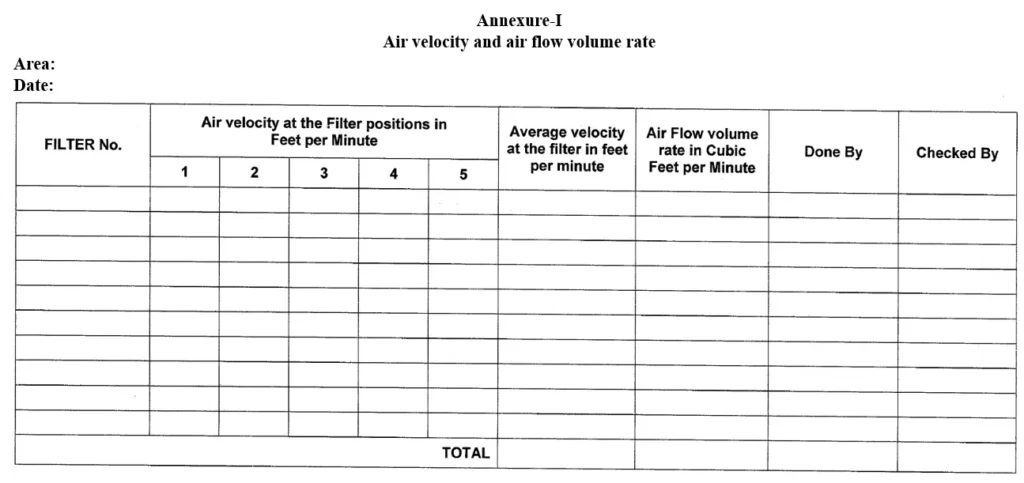

5.3.1.5 Measure the airflow velocity at each test position for at least 10 seconds duration and note down the readings in the record as per the Annexure-I.

5.3.1.6 Find the average value of the same and record as per the Annexure-I.

5.3.1.7 Calculate the Air Flow volume rate of the air by applying the formula.

CFM= Average velocity of air (feet/min) x Area of the filter (square feet).

5.3.1.8 Note down the value obtained in the record as per the Annexure-I.

5.3.2 To determine the air changes per hour (ACPH):

5.3.2.1 Take the dimensions of the clean room (in feet) and calculate the room volume in cubic feet.

5.3.2.2 Determine the Air Flow Volume rate across the individual filters as per the procedure in 5.3.1.7.

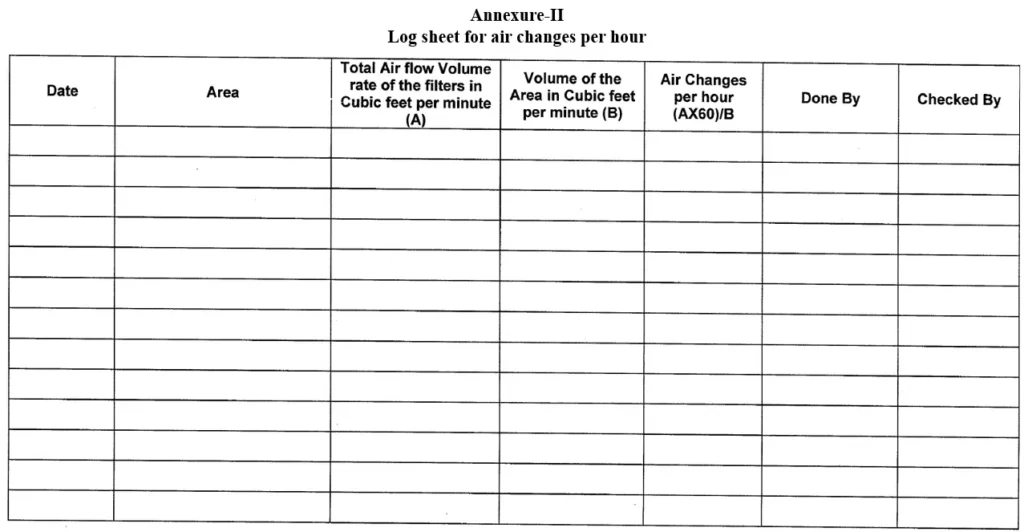

5.3.2.3 Determine the total Air Flow volume rate by adding Air Flow volume rates of the individual filters of the respective clean room.

5.3.2.4 Determine the Air Changes per hour by applying the formula.

5.3.2.5 ACPH = (Total Air Flow Volume rate in CFM x 60) / Total room Volume in cubic feet.

5.3.2.6 Ensure the minimum and maximum velocity and subsequent airflow across the supply grill should be within the design specification range to achieve the specified range of air changes and differential pressure of the clean room. The variation among the average velocity across the terminal grill supplying to the same room should not be more than ± 20%.

5.3.2.7 Note down the values as per the Annexure-II.

6.0 ABBREVIATIONS:

SOP – Standard Operating Procedure.

ENG – Engineering Department.

ACPH – Air changes per Hour.

CFM – Cubic feet per minute.

MM – Millimeter.

7.0 REFERENCES:

Nil.

8.0 LIST OF ANNEXURES:

Annexure-I: Air Velocity and Air Flow volume rate.

Annexure-II: Log sheet for Air Changes per Hour.