1.0 PURPOSE:

2.0 SCOPE:

This SOP for handling of alarms for critical equipments is applicable in Production department at (Company name).

3.0 DEFINITIONS:

3.1 Critical Alarms (C):

3.2 Critical Alarms for safety of machine (CM):

3.3 Non critical alarms (NC):

4.0 RESPONSIBILITY:

4.1 Production operator is responsible to follow the SOP.

4.2 Production Department Heads or designee are responsible for review of all alarms.

4.3 Head-QA is responsible to ensure Compliance of the procedure.

5.0 PROCEDURE:

5.1 Whenever the alarm will generate by the equipment, immediately the operator shall be acknowledge the alarm by logging in the operator password. The same shall be intimated (if required) to the immediate superior or the head of the department.

5.2 The immediate supervisor shall assess the nature of the alarm and shall decide whether the alarm comes under which category.

5.3 If the generated alarm comes under non-critical category, then the alarm shall be acknowledged and proceed ahead for ongoing process without recording or addressing it.

5.4 If the generated alarm comes under critical for machine category, not required to record but needs to be rectified before proceeding ahead for process for safety point of view of machine if required.

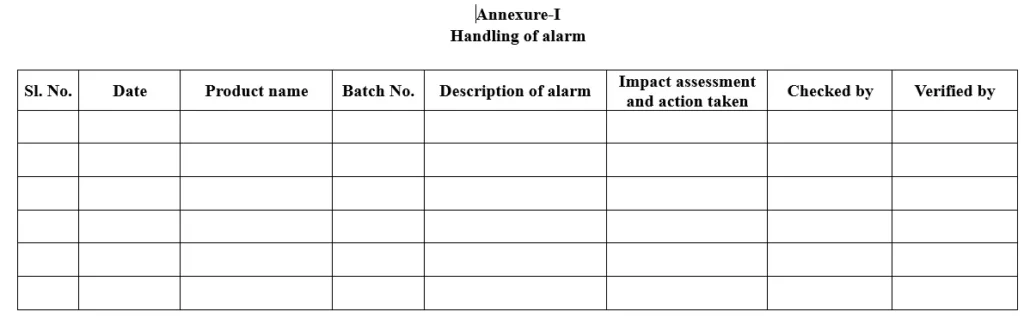

5.5 If the generated alarm comes under critical category, then the alarm shall be addressed in the alarm handling log in Annexure-I and immediate supervisor will inform to head of the department/designee and/or QA head/designee and follow the instruction.

5.6 Based on the impact assessment, decision will be taken for further operation.

5.7 Break down request for the equipment shall be logged whenever required followed by incident and CAPA if required.

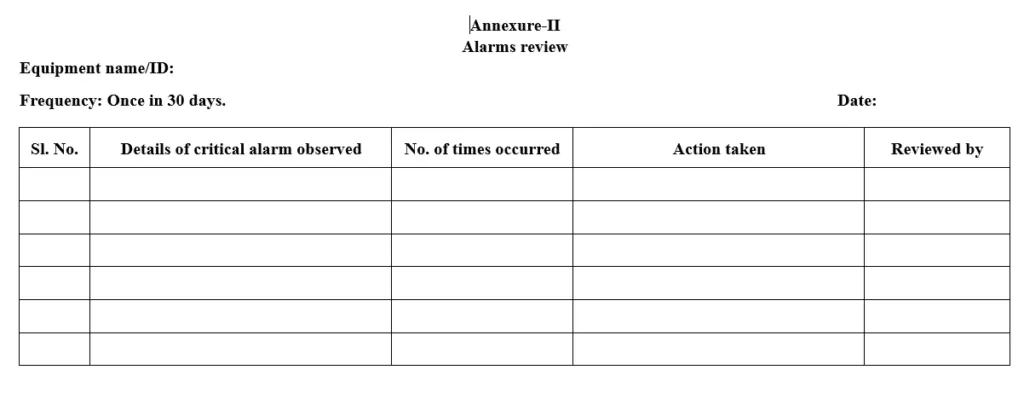

5.8 All the critical alarms shall be reviewed by the user department head/designee once in every 30 days and shall be recorded in Annexure-II.

5.9 List of critical equipment’s covered for alarm handling is to be maintained.

6.0 ABBREVIATIONS:

6.1 SOP :Standard Operating Procedure

6.2 C :Critical

6.3 NC :Non-Critical

6.4 PLC :Programmable logical control

6.5 CM :Critical for machine

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Handling of Alarms

Annexure-II: Alarms review.

Also read: SOP for Critical Area Practices

Also read: SOP for Polishing of Punches and Dies