1.0 PURPOSE:

2.0 SCOPE:

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Engineering personnel is responsible for Dumping challenge test.

4.2 Engineering head is responsible to ensure compliance.

5.0 PROCEDURE:

5.1 Ensure that Control panel power is ON.

5.2 Ensure that compressed air is available with 6 Kg/cm2 pressure.

5.3 Ensure that the distribution pump suction and discharge Diaphragm valves are open.

5.4 Dumping challenge test for Purified water & WFI system:

5.4.1 How to generate fault:

5.4.1.1 Log in supervisor password.

5.4.1.2 Select Auto mode from the HMI in control panel.

5.4.1.3 In HMI select set parameters and then set conductivity action limit less than the actual conductivity.

Example: If actual conductivity is 0.9 µS/cm then set action limit as 0.5 µS/cm.

5.4.1.4 Check on HMI which will show High conductivity alarm.

5.4.1.5 Dumping valve will get open automatically and system start dumping the water.

5.4.2 Remedies:

5.4.2.1 Again set action limit value as per original setting.

5.4.2.2 Dumping valve will get closed automatically.

5.5 Dumping challenge test for RO:

5.5.1 How to generate fault:

5.5.1.1 Log in supervisor password.

5.5.1.2 Select Auto mode from the HMI in control panel.

5.5.1.3 In HMI select set parameters and decrease the conductivity setting set point less than the actual conductivity.

5.5.1.4 Check on HMI which will show “RO conductivity high” alarm.

5.5.1.5 Auto flushing valve and Recirculation valve will get open automatically and system start recirculation till the Conductivity value gets within limit

5.5.1.6 Again increase the conductivity setting as per the system.

5.5.1.7 Recirculation valve will get closed automatically.

5.5.1.8 In HMI select set parameters and decrease the pH setting set point less than the actual pH.

5.5.1.9 Check on HMI which will show “RO pH High” alarm.

5.5.1.10 Auto flushing valve and Recirculation valve will get open automatically and system start flushing till the pH value gets within limit.

5.5.2 Remedies:

5.5.2.1 Again set the pH value as per the original setting.

5.5.2.2 Recirculation valve will get closed automatically.

5.6 Dumping challenge test for EDI:

5.6.1 How to generate fault:

5.6.1.1 Log in supervisor password.

5.6.1.2 Select Auto mode from the HMI in control panel.

5.6.1.3 In HMI select set parameters and decrease the conductivity setting set point less than the actual conductivity.

5.6.1.4 Check on HMI which will show “EDI conductivity high” alarm.

5.6.1.5 Dumping port valve will get open automatically and system start recirculation to RO feed tank.

5.6.2 Remedies:

5.6.2.1 Again set action limit value as per original setting.

5.6.2.2 Dumping valve will get closed automatically.

5.6.2.3 Dumping challenge test perform weekly once.

5.7 Frequency:

5.7.1 Dumping challenge test perform once in a month or after any major change or breakdown of the system.

6.0 ABBREVIATIONS:

SOP – Standard Operating Procedure

HMI – Human Machine Interface

NMT – Not More Than

RO – Reverse Osmosis

EDI – Electro deionization

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

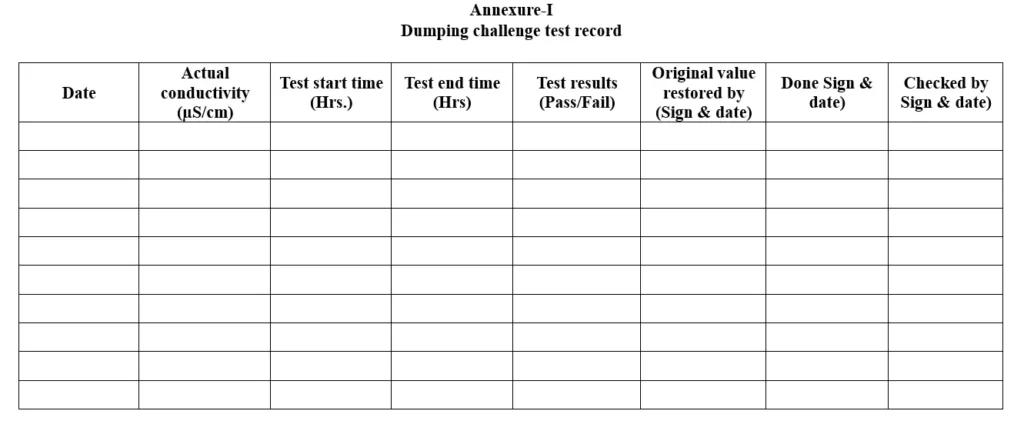

Annexure-I: Dumping challenge test record.