1.0 PURPOSE:

2.0 SCOPE:

This procedure is applicable for usage and control of machine lubricant’s in OSD block at (Company name).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Production Operator is responsible to follow the procedure.

4.2 Production Officer/Executive is responsible for the execution of the procedure.

4.3 Head-Production is responsible for ensure the compliance of the procedure.

5.0 PROCEDURE:

5.1 During qualification of manufacturing equipment and machine it should be ensured that there is no possibility of leakage of lubricant into the products.

5.2 Lubricant’s which are used for the lubrication of machine parts that comes in contact with the product should be non-toxic (food grade) and should be purchased from approved supplier as per machine manufacturer recommendation. Certificate for its toxicity and product data sheet should be obtained from the supplier.

5.3 Lubricants should not come in contact with product or container / closure in any way which might alter the safety, identity, quality, or purity of the product.

5.4 List of lubricant’s approved for use in manufacturing equipment and machine, list of approved supplier and specification should be established and maintained at unit level.

5.5 On receipt of the consignment of lubricant’s, ensure the correctness of material, quantity received and raise the test request form to Quality control for checking of physical parameter like viscosity, specific gravity and bioload.

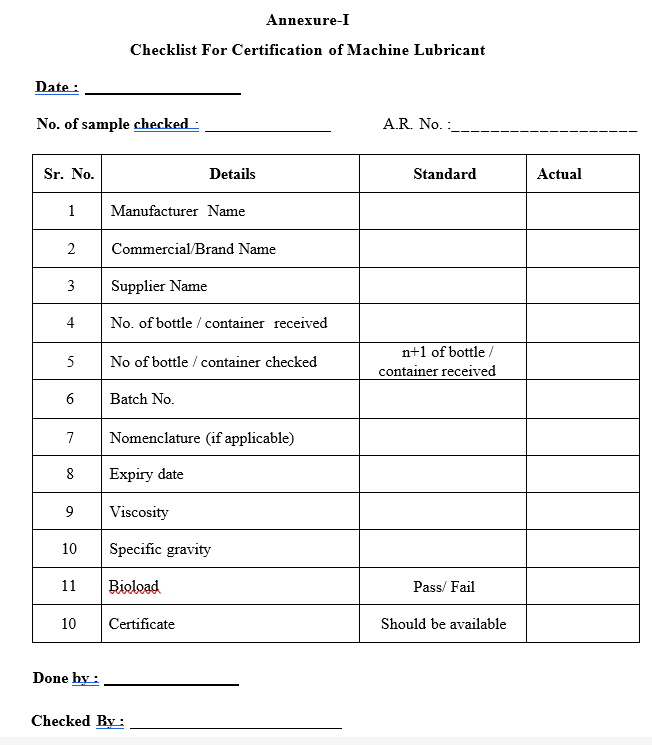

5.6 After receipt of sample quality control should certify the suitability of these lubricant’s by checking n +1 containers against the standard pack and referring to attached checklist refer Annexure-I and put “approved/ rejected” label on each of the bottle/ container.

5.7 Only approved packs should be issued from store department to user department against issue slip.

5.8 After opening the original seal from supplier the container should be labeled as:

Seal Opened on:

Valid up to:

Sign & date:

5.9 Valid up to date should be within 2 years from date of opening of the seal of container or before expiry date of the lubricant whichever is earlier.

5.10 The lubricant’s should be used within the valid date only.

5.11 In case of any discrepancies it should be informed to quality assurance department for further action.

6.0 ABBREVIATIONS:

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Checklist for certification of lubricant.

1 thought on “Procedure For Usage And Control Of Machine Lubricants”

Pingback: SOP for operation and cleaning of slurry preparation vessel -