1.0 PURPOSE:

2.0 SCOPE:

This procedure is applicable for operation and cleaning of Stirred Water Bath used in Quality control laboratory at (Company name).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Analyst /Microbiologist: Responsible for execution of the procedure specified in SOP.

4.2 Head Quality Control/QA: Responsible for ensuring that the compliance to the procedure specified in this SOP.

5.0 PROCEDURE:

5.1 Preliminary check:

5.1.1 Check and ensure that the equipment is clean and suitable for starting the operation. If it is not, clean with a soft cloth duster as mentioned in cleaning procedure.

5.2 Basic operation:

5.2.1 Pour purified water in the bath to the required level. The water level should be in between the minimum and maximum level markings in the bath.

5.2.2 Connect the power supply cord to the mains and switch ‘ON’ the water bath by pressing the illuminated ‘ON / OFF’ switch.

5.2.3 The Digital Temperature Controller cum Indicator (DTC) will indicate the actual temperature of water.

5.2.4 Set the desired temperature by pressing the PRESS to SET switch and adjusting the SET knob and wait till the set temperature is achieved.

5.2.5 Place the articles with media, samples etc. which needs to be heated in water bath in proper glassware.

5.2.6 After usage of the equipment put ‘OFF’ the equipment.

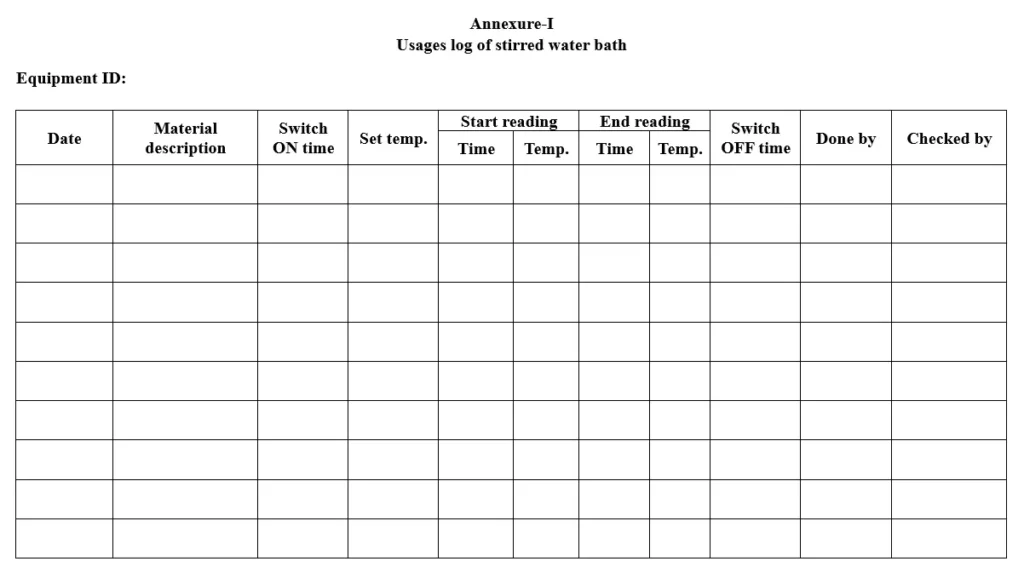

5.2.7 Record the details in usage log of water bath as per Annexure-I.

5.3 Cleaning:

5.3.1 Use mild detergents, purified water or approved cleaning agents for cleaning of SS surfaces of the water bath.

5.3.2 Do not allow cleaning liquids or sprays to enter the controller vents.

5.3.3 Ensure the water level. A line on water level indicator, on left, indicates the minimum water level.

5.4 Maintenance of Heater:

5.4.1 The heater should be kept clean. Always use purified water to avoid scaling on the heater.

5.4.2 If deposits build up on heater, they may be removed by scrubbing with a nonmetallic abrasive pad.

5.4.3 Ensure that the water in the bath is replaced regularly.

5.5 Calibration:

5.5.1 Calibrate the temperature controller from the outside party/in-house by engineering department as per the engineering SOP.

Note: If the equipment does not comply with any of the calibration parameters, then follow the relevant procedure of the equipment breakdown.

6.0 ABBREVIATIONS:

SOP : Standard Operating Procedure

QA : Quality assurance

SS : Stainless steel

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Usage Log of Stirred Water Bath.