1.0 PURPOSE:

2.0 SCOPE:

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Analyst / Microbiologist: The Analyst/Microbiologist is responsible for carrying out the procedures outlined in this document.

4.2 Executive /designee: Executive or designee is responsible for ensuring that, the procedure followed for usage, maintenance of fogger is followed as specified in this document.

4.3 Head Quality Control: The Head Quality control is responsible for overall compliance of the procedure mentioned in this document.

4.4 Quality assurance: The QA is responsible for ensuring that, compliance of the procedure.

5.0 PROCEDURE:

5.1 Cleaning and preliminary check:

5.1.1 Clean the internal surface of the fogger followed by external surface using the lint free duster dipped in disinfectant.

5.1.2 Check the integrity of the equipment parts, if any abnormality observed immediately inform to supervisor.

5.1.3 Never attempt to service the machine or access its internal components while it is plugged into an electrical outlet.

5.2 Basic operation:

5.2.1 Ensure that fogger is cleaned.

5.2.2 Unscrew and take out the fogger lid from the formulation tank.

5.2.3 Wash the formulation tank with purified water.

5.2.4 Close the lid of the fogger by rotating it securely onto the tank.

5.2.5 Add the sufficient quantity of disinfectant in the formulation tank through the fill cap keep in the area to be fumigated.

5.2.6 Plug the power supply cable of fogger in main electric supply.

5.2.7 Adjust the angle of the fogger head with the adjustable locking handle.

5.2.8 Switch ON the power and electrostatic indicator light and leave the area.

5.2.9 The machine consists blower assembly it directs a large amount of air through the nozzle system.

5.2.10 Nozzle direct the air to create a swirling effect of the air mass as it leaves the nozzle.

5.2.11 In the center of this exiting swirling air, a liquid is delivered to the nozzle by a liquid supply spout tube injects formulation. The liquid is supplied to the nozzle through negative pressure generated by the exiting air.

5.2.12 Fogger spray the disinfectant at flow rate of 0-280 ml/min and throw a distance of 30-50 feet.

5.2.13 The droplet size of the output is depend on the viscosity of the disinfectant.

5.2.14 1000 ml of disinfectant is sufficient to fumigate 1000 cubic feet area.

5.3 Cleaning after activity:

5.3.1 Unscrew and take out the fogger lid from the formulation tank.

5.3.2 Drain if any disinfectant remains in the formulation tank.

5.3.3 Wash the formulation tank with purified water.

5.3.4 Close the lid of the fogger by rotating it securely onto the tank.

5.3.5 Plug the power supply cable of fogger in main electric supply.

5.3.6 Switch ON the power and electrostatic indicator light.

5.3.7 Run the fogger for few minutes with purified water.

5.3.8 Unscrew and take out the fogger lid from the formulation tank and drain the water from the tank.

5.3.9 Fix the lid of fogger by rotating the lid on the tank and run for few minutes with empty tank.

5.3.10 Wipe with a lint free cloth and keep dry.

6.0 ABBREVIATIONS:

QA : Quality Assurance

QC : Quality control

No. : Number

SOP : Standard operation procedure

7.0 REFERENCES:

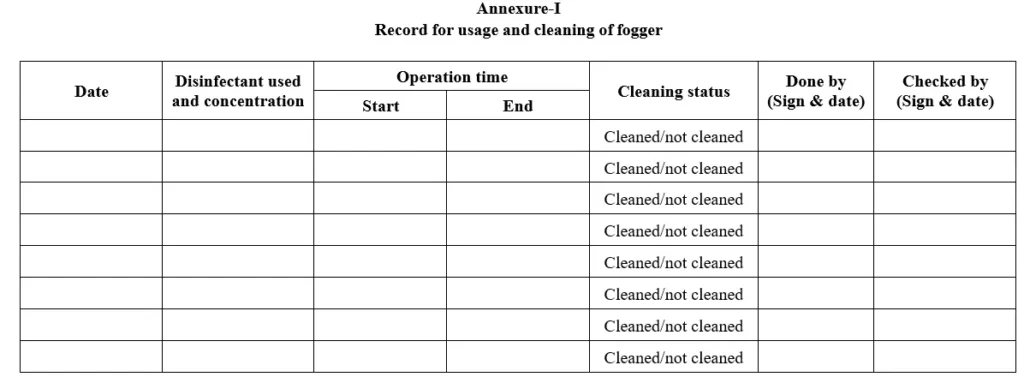

8.0 ANNEXURES:

Annexure-I: Record for usage and cleaning of fogger.