1.0 PURPOSE:

2.0 SCOPE:

This procedure for Differential pressure measurement across HEPA Filter is applicable at (Company mane).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Engineering personnel shall responsible for Differential pressure measurement across HEPA Filter.

4.2 Engineering head shall responsible to ensure compliance.

5.0 PROCEDURE:

5.1 Frequency:

5.2 Measurement of Differential Pressure across Terminal HEPA filters of AHU:

5.2.1 Ensure calibration validity of the Magnehelic gauge used for measurement.

5.2.2 Connect the upstream of the HEPA filter to the HIGH side port of the Magnehelic gauge and the downstream of the filter to the LOW side port of the Magnehelic gauge.

5.2.3 Start the Air handling unit or the related equipment and allow the system to stabilize for 5 minutes.

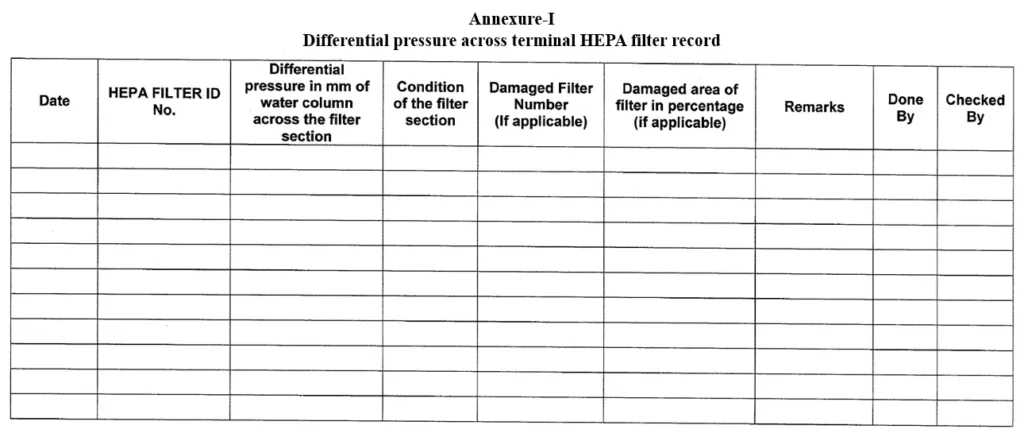

5.2.4 Check the reading indicated on the Magnehelic gauge and record the reading in the document as per the Annexure-I.

5.2.5 The differential pressure across HEPA filter shall be in the range of 25 mm of WC to 60 mm of WC.

5.2.6 In case the reading exceeds 50 mm WC, the filter shall be treated as due for replacement and the filter shall be replaced before the reading exceeds 60 mm WC.

5.2.7 In case the current reading falls below the reading last recorded, it is indicative of ruptured filter or drop in CFM across the filter. Check the velocity of air flow at the HEPA filter and compare the reading observed with the last recorded data during last validation activities.

5.2.8 In case of ruptured filter, if the damaged area of the filter is less than 5% of the total filter area then repair it with either silicon sealant or any other suitable substance. If the ruptured area exceeds 5% of the total filter area then, replace the filter.

5.2.9 Carry out PAO testing of the repaired filter or new filter.

6.0 ABBREVIATIONS:

6.1 SOP – Standard Operating Procedure.

6.2 mm WC – Millimeter of water column.

6.3 CFM – Cubic feet per minute.

6.4 PAO – Poly Alfa Olefin.

6.5 HEPA – High efficiency Particulate Air.

6.6 AHU – Air handling unit.

7.0 REFERENCES:

8.0 LIST OF ANNEXURES:

Annexure-I: Differential pressure across Terminal HEPA filter record.