1.0 PURPOSE:

2.0 SCOPE:

3.0 DEFINITION:

4.0 RESPONSIBILITY:

4.1 Personnel engineering is responsible to perform the passivation.

4.2 Head-engineering/designee is responsible to ensure the compliance of the procedure.

5.0 FREQUENCY:

6.0 PROCEDURE:

6.1 Ensure that the tank is filled with water.

6.2 Passivation shall be carried out with 5% Nitric acid solution.

6.3 Purified water circulation loop shall be passivated as per the following procedure:

6.3.1 Initial Water rinse:

6.3.1.1 Take 25-60% by volume of water in the storage tank.

6.3.1.2 Ensure the purified water pump suction valve and delivery valve of pump are open.

6.3.1.3 Start the purified water pump to re-circulate the water for the period of 30 minutes.

6.3.1.4 Drain the water from the return loop drain valve until water level is low in the tank.

6.3.1.5 Stop the purified water pump.

6.3.1.6 Drain the water from the tank through drain valve.

6.3.1.7 Check and ensure all the outlets or ports are opened and no water should be present in the loop. Close all the valves of the loops after ensuring drainage.

6.3.2 Acid wash:

6.3.2.1 Fill the purified water tank with water till level L1 indicator glows.

6.3.2.2 Prepare Nitric acid solution by adding 28 litres of nitric acid solution having 70% concentration to the purified water in purified water tank.

Note: wear safety gloves, face-eye-masks before preparing solution.

6.3.2.3 Fill the purified water tank to make the volume till level indicator L2 glows.

6.3.2.4 Start the purified water pump.

6.3.2.5 Circulate the Nitric acid solution for 60 minutes through the loops and tank.

6.3.2.6 Stop the purified water pump.

6.3.2.7 Drain the solution completely from the drain valves of Purified water tank and loops of all user points respectively.

6.3.2.8 Close the purified water tank drain valve and loop drain valves.

6.3.3 Final water rinse:

6.3.3.1 Collect Purified water in the Purified water tank until reaches to high level.

6.3.3.2 Start the purified water pump and continue circulation for 30 minutes.

6.3.3.3 Drain the water from the return loop drain valve until water level is low in the tank.

6.3.3.4 Drain the all user points, take the supply and return loop sample and sample shall be send to QC for PH and conductivity test.

6.3.3.5 Repeat the above cycle of section 6.3.3.1 to 6.3.3.4 until the PH of purified water in return loop reaches 5 to 7.

6.3.3.6 Sanitize the loops and purified water tank as per SOP for procedure of sanitization of purified water storage and distribution system.

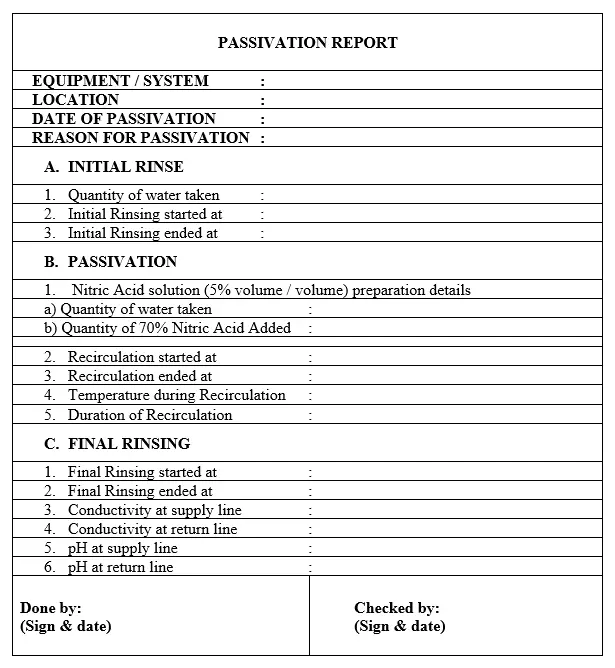

6.3.3.7 Record the passivation details in passivation report.

6.4 Tanks and small parts (if unassembled) shall be passivated as per the following procedure:

6.4.1 Rinse with purified water on outer surfaces of tank or parts.

6.4.2 Prepare the 5% Nitric acid solution with purified water as per the surface of the tank or parts.

6.4.3 Spray Nitric acid solution onto outer surfaces of tank and wipe it with wet cloth. Dip the parts in acid solution and then in purified water.

6.4.4 Rinse outer surfaces with purified water for 30 minutes.

Note: During passivation remove conductivity sensor.

7.0 ABBREVIATIONS:

8.0 ENCLOSURES:

9.0 REFERENCE: