1.0 PURPOSE:

2.0 SCOPE:

This SOP is applicable for Operation and Calibration of Micropipettes used in Quality Control Department at (Company name).

3.0 REFERENCE:

4.0 DEFINITION:

5.0 RESPONSIBILITY:

Execution: Analyst QC; Checking: Executive QC or Designee; Accountability: Head QC or Designee

6.0 FREQUENCY:

7.0 PROCEDURE:

7.1 Operation:

7.1.1 Volume setting:

7.1.1.1 Press holds the lateral catch and adjusts the volume by turning the control button.

7.1.1.2 Always carry out volume setting from the higher to the lower value. i.e., first go above the desired volume and then return to the lower value.

7.1.2 Fitting the tip to the pipette shaft cone:

7.1.2.1 Hold the pipette with right hand.

7.1.2.2 Take out a pipette tip carefully and fit it to the pipette shaft cone by turning the tip tightly in the anti- clock wise direction.

7.1.3 Aspirating liquid:

7.1.3.1 The liquid which is to be aspirated is taken from a suitable vessel.

7.1.3.2 Attach suitable tip to the pipette firmly.

7.1.3.3 Press down the control button to the first stop (measuring stroke).

7.1.3.4 Immerse the pipette tip vertically approx. 3 mm into the liquid.

7.1.3.5 Leave the tip immersed in the liquid for about 3 seconds.

7.1.3.6 Allow the control button to slide back slowly.

7.1.3.7 Pull the tip out of the liquid slowly.

7.1.3.8 To remove any remaining droplets, dab with non-fibrous cellulose material. When doing so, ensure that no liquid comes out of the tips.

7.1.4 Dispensing the sample:

7.1.4.1 Hold the tips at an angle against the inside wall of the tubes.

7.1.4.2 Press down the control button slowly to the first stop (measuring stroke) and wait until the liquid stops flowing.

7.1.4.3 Press down the control button to the second stop (blow-out) until the tip is completely empty.

7.1.4.4 Hold down the control button and pull the tip up the inner wall of the tube.

7.1.4.5 Allow the control button to slide back slowly.

7.1.4.6 Tip is ejected by pressing the control button to the final stop.

7.1.4.7 Rinse the tip once with the sample liquid transferring the sample to the respective vessel.

7.1.5 Precautions during pipetting:

7.1.5.1 Do not adjust the volume beyond the specified volume.

7.1.5.2 Do not touch the lower half portion of tips during fitting of tips to the pipette shaft cone.

7.1.5.3 Do not lay down the pipette when a filled pipette tip is attached.

7.1.5.4 Do not immerse the tip more than half of its length during aspiration.

7.2 Calibration:

7.2.1 Checking calibration (Performance test):

7.2.1.1 Take a clean, dry glass beaker. Keep it on the weighing pan of analytical balance and tare it.

7.2.1.2 Carefully fit tip onto the pipette shaft cone.

7.2.1.3 Pre-rinse the tip with purified water few times.

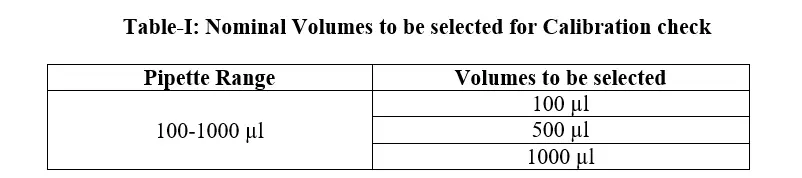

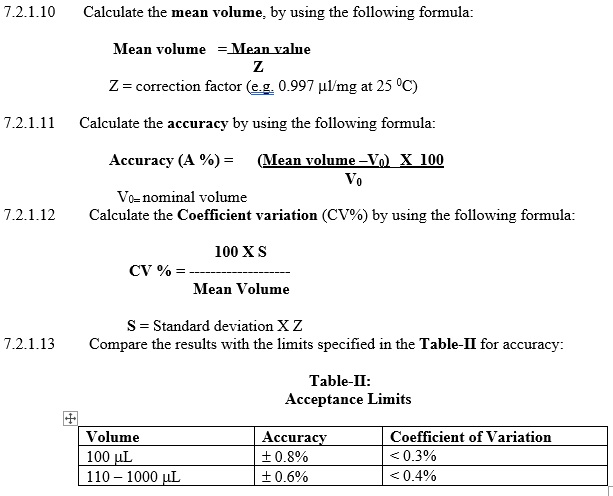

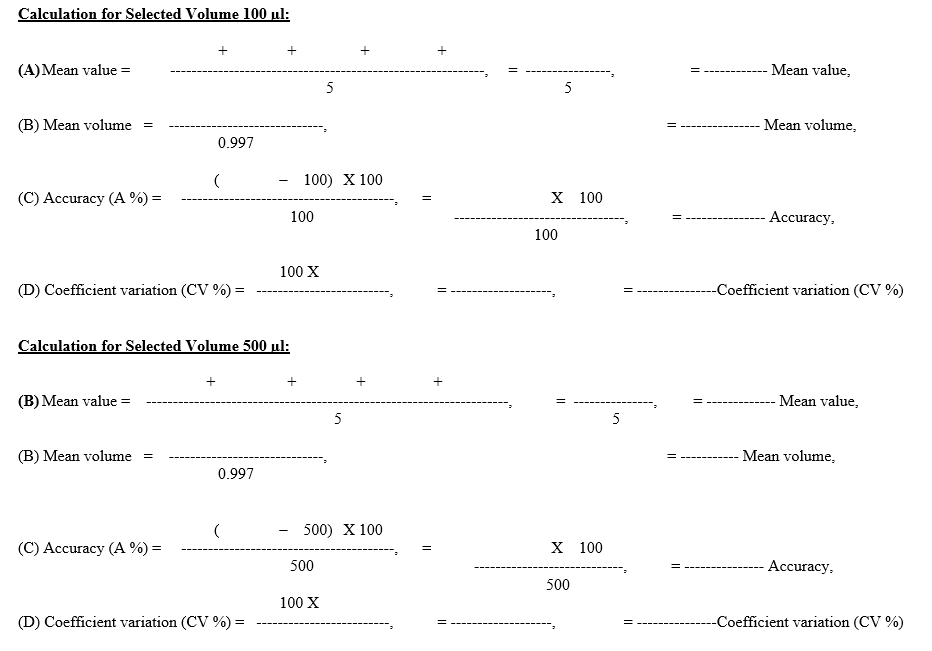

7.2.1.4 Then perform the calibration check with purified water by pipetting the selected Volume (as per Table-I) five times.

7.2.1.5 Carefully aspirate the liquid, keeping the pipette in vertical.

7.2.1.6 Pipette purified water in to tare beaker and record the weight in mgs in the Annexure-I.

7.2.1.7 Repeat the procedure five times by tarring the beaker weight after recording each weight.

7.2.1.8 Repeat the procedure for all the volumes mentioned in Table-I.

7.2.1.9 Record the details in the in Annexure-I.

8.0 ABBREVIATIONS:

SOP : Standard Operating Procedure

QC : Quality Control

QA : Quality Assurance

µL : Micro liter

Mg : Milligram

9.0 ENCLOSURES:

Annexure-I: Record of results for micropipette calibration.

8 thoughts on “Procedure for Operation and Calibration of Micropipettes”

Pingback: SOP for Operation and Calibration of Bursting Strength Test Apparatus -

Pingback: Procedure for cleaning of laboratory glassware -

Pingback: Procedure for Operation, Cleaning and Calibration of Ultra Violet Cabinet -

Pingback: SOP for testing and release of in-process, semi-finished and finished product samples -

Pingback: Operation, cleaning and calibration of pH meter -

Pingback: SOP for operation and cleaning of visual inspection board -

Pingback: SOP for operation, cleaning and calibration of Scott volumeter -

Pingback: SOP for management of water quality -