1.0 PURPOSE:

2.0 SCOPE:

This procedure is applicable for preventive maintenance of analytical instruments such as HPLCs and GCs available in the quality control laboratory of (Company name).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Analyst: For performing the preventive maintenance of analytical instruments.

4.2 Sectional head/Group Leader: Shall ensure that preventive maintenance is performed as per the frequency.

4.3 Department Head or his designee to ensure compliance of the SOP.

5.0 PROCEDURE:

5.1 Preventive maintenance program for HPLCs:

5.1.1 Remove the suction filters of HPLCs and clean the filter in a beaker containing dilute nitric acid and sonicate for five minutes, immediately wash the filter with plenty of purified water and sonicate for five minutes. Finally rinse the filters with methanol and sonicate for five minutes.

5.1.2 Replace the cleaned filters back to the instrument.

5.1.3 Remove the inline frits and if inline frits are of stainless steel make clean the frits as recommended from 5.1.1 to 5.1.2, if it is of ceramic frits check the quality inline frit filters if is changed colour to black/brown completely replace the filter (generally new frits are of white in colour).

5.1.4 Remove the inlet and outlet check valves of HPLCs and place the check valves in a beaker and clean with the aid of sonication in purified water and followed by methanol and replace the check valves.

5.1.5 Purge all the channels of HPLC with methanol for at least 5 minutes and connect the flow restrictor or union and flush the entire system with all channels in operation (each channel 25%) for at least 15 minutes.

5.1.6 Place filtered and degassed purified water into any of the channel and perform the noise drift and lamp intensity test as per operation, cleaning and calibration SOP.

5.1.7 Record the observations in preventive maintenance performance record as per the Annexure-I.

5.1.8 Frequency of preventive maintenance:

5.1.8.1 Once in 30 days + 7 days.

5.1.9 Acceptance criteria:

5.1.9.1 Should meet the acceptance criteria of individual instrument make.

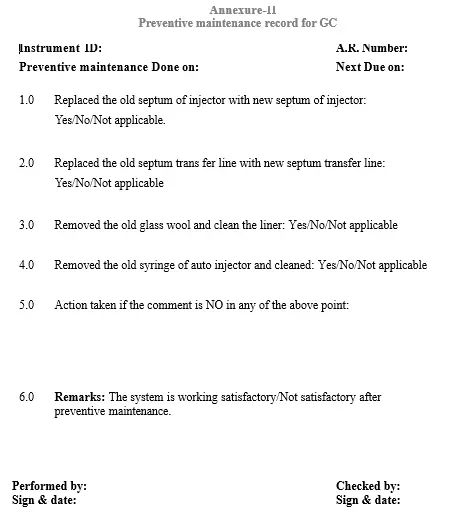

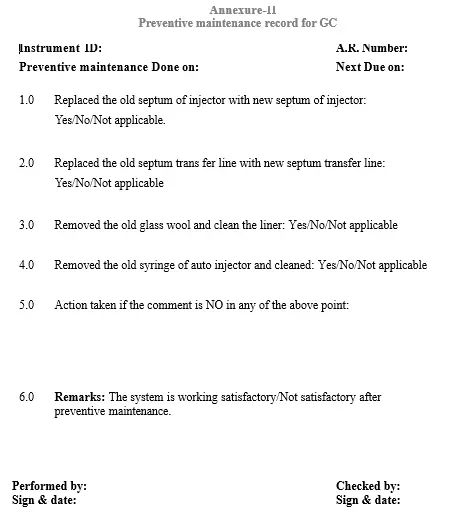

5.2 Preventive maintenance program for GCs:

5.2.1 Remove the septum of the injector and headspace transfer line and replace the septum with new septum.

5.2.2 Remove the liner from the instrument, carefully remove the glass wool and clean the liner with methanol followed by dichloromethane finally with purified water, rinse the liner with acetone and dry the liner at 105°C for one hour remove the liner from the over cool and place new glass wool into the liner.

5.2.3 Remove the syringe of the auto sampler (liquid injector) clean the syringe with methanol and finally with water dry the syringe at 105°C in an oven for 30 mins.

5.2.4 Fix the syringe carefully to auto-injector.

5.2.5 Record the observations in preventive maintenance performance record as per the Annexure-II.

5.2.6 Frequency of preventive maintenance:

5.2.6.1 Once in 30 days + 7 days.

Note: Preventive maintenance shall be performed before performing calibration and preventive maintenance record shall be updated.

6.0 ABBREVIATIONS:

HPLC : High Performance Liquid Chromatography

GC : Gas Chromatography.

7.0 REFERENCES:

Nil.

8.0 LIST OF ANNEXURES:

Annexure-I: Preventive maintenance record for HPLC.

Annexure-II: Preventive maintenance record for GC.