1.0 PURPOSE:

To define the procedure for integrity testing of vent filter by Bubble point test.

2.0 SCOPE:

This procedure for integrity testing of vent filter is applicable at (Company name).

3.0 DEFINITION:

4.0 RESPONSIBILITY:

4.1 Personnel engineering is responsible to perform the test.

4.2 Head-engineering/designee is responsible to ensure the compliance of the procedure.

5.0 FREQUENCY:

Integrity Testing: Monthly before sanitization of distribution system or whenever

required.

Replacement: Three months before validity of vendor certificate (or) if integrity Test

fails.

6.0 PROCEDURE:

7.1 Materials Required:

7.1.1 Compressed air or Nitrogen

7.1.2 Calibrated Pressure gauge and regulator

7.1.3 Filter, Filter housing

7.1.4 Beaker

7.1.5 Silicon Tubing

7.1.6 Filter adapters

7.2 Record the filter catalog No., lot number and also include physical observations.

7.3 Wet the filter to be tested with the appropriate solvent (water for hydrophilic filters,

70% IPA for hydrophobic filters).

7.2 Preparation of 70% v/v IPA:

7.2.1 Issue IPA from Warehouse by giving the material requisition.

7.2.2 Dispensed IPA shall be carried in a closed container to the preparation area.

7.2.3 The preparation of the 70% v/v IPA shall be done in purified water system area.

7.2.4 The formula for preparation of IPA shall be taken as

Y = 70% x “R”

= 70/100 x “R”

Where, “R” is the quantity of 70% IPA solution to be prepared.

“Y” is the quantity of 100% IPA to be taken.

7.2.5 Now “Y” liters of IPA is to be taken into the measuring cylinder / suitable vessel and sufficient quantity of purified water is to be added till “R” Liters.

Example:

Let us assume,

Requirement of 70% v/v IPA= 10 Liters

i.e. R=10 Liters

Therefore as per the formula:

Y = 70/100 x “R”

= 70/100 x 10

= 7 Liters.

7.2.6 Now 7 liters of IPA is to be taken into the measuring cylinder and sufficient quantity

of purified water is to be added till 10 Liters.

7.2.7 At the end of the day, the left out 70% v/v IPA solution shall be discarded in drain by mixing with twice of purified water.

7.2.8 The IPA prepared to be consumed within 24 Hours.

7.3 Place the wetted filter in the appropriate housing.

7.4 Connect the outlet fitting from the compressed air or Nitrogen pressure regulator to the upstream side of the test filter. Check that the gauge which is connected to the pressure regulator has subdivisions of at least 5 PSI, and has the capacity to measure up to 50 PSI. A calibrated pressure gauge shall be used to measure the pressure.

7.5 Connect a piece of flexible tubing (Silicon tube may be used) from the downstream port of the test filter into a beaker filled with water.

7.6 Starting from zero pressure, gradually increase the pressure to the test filter using the

Pressure regulator.

7.7 Observe the submerged end of the tubing for the production of bubbles as the upstream pressure is slowly increased in 5 PSI increments. Note the rate that the bubbles appear for the end of the submerged tube.

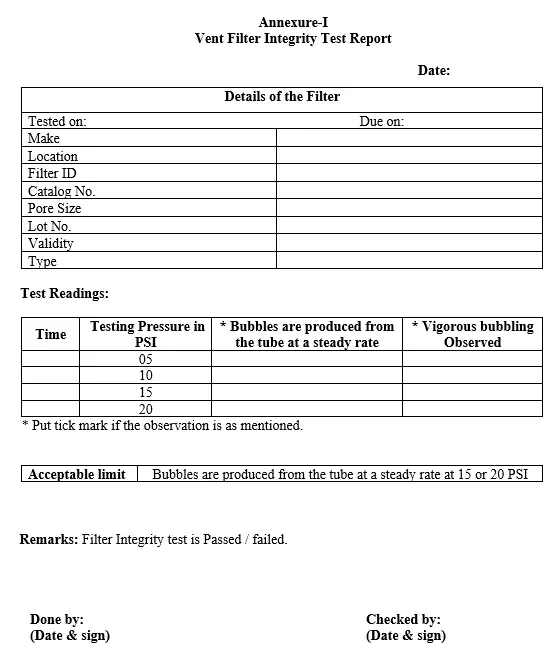

7.8 The bubble point of the test filter is reached when bubbles are produced from the tube at a steady rate. Record the pressure to the nearest 5 PSI as indicated on the pressure gauge as per Annexure-I.

7.9 If the recorded pressure is greater than or equal to the minimum expected bubble point in the range 15 to 20 PSI the filter is integral. If the recorded pressure is lower than the minimum bubble point range the filter has failed the integrity test.

7.10 The Filter shall be replaced three months before validity of vendor certificate (or) if integrity Test fails.

7.11 Test Considerations:

7.11.1 Ensure that the filter is thoroughly and uniformly wet (preferably for 30 minutes) such that all the pores are filled with 70% IPA/water. Failure to wet the filter may result in premature air flow resulting in false failure.

7.11.2 Diffusive flow of air through the filter will occur at pressures lower than the Bubble point. Ensure that the pressure recorded is in fact the pressure at which a Steady stream of bubbles is noted.

7.11.3 If failure occurs open the filter housing to ensure that the filter is installed correctly in the housing. Replace the housing cover and retest. If another failure is recorded remove and dispose of the filter element.

7.0 ABBREVIATIONS:

IPA : Iso Propyl Alcohol

No. : Number

PSI : Pounds per square inch

8.0 ENCLOSURES:

Annexure-I: Filter Integrity test report