1.0 PURPOSE:

2.0 SCOPE:

Procedure for Calibration of Dosing Pumps is applicable to all the Dosing Pumps related to the water plant at (Company name).

3.0 DEFINITIONS:

4.0 RESPONSIBILITY:

4.1 Engineering personnel shall responsible for Calibration of Dosing Pumps.

4.2 Engineering head shall responsible to ensure compliance.

5.0 PROCEDURE:

5.1 The calibration of dosing pumps shall be performed quarterly.

5.2 Dosing pumps shall be calibrated by measuring the output quantity of solution for a specified time at different percentages of flow shown on the pump.

5.3 Before starting the calibration keep ready calibrated timer and measuring cylinder.

5.4 Ensure that the connected system is not in operation.

5.5 Stop the dosing pump and disconnect the discharge pipe from the Service line.

5.6 Set the dosing pump at 100 % flow.

5.7 Start the timer and start the dosing pump simultaneously and collect the solution from the discharge into measuring cylinder.

5.8 After 5 minutes stop the pump and timer simultaneously and record the result.

5.9 Calculate discharge for one hour, based on the quantity of solution collected in 5 minutes.

5.10 Similarly perform the calibration at 25%, 50% and 75% of the flows.

5.11 If the results are within the limit of ± 5 %, pump shall be used for the operation. If the results are out of limit then rectification/ replacement of the pump shall be done and recalibrated.

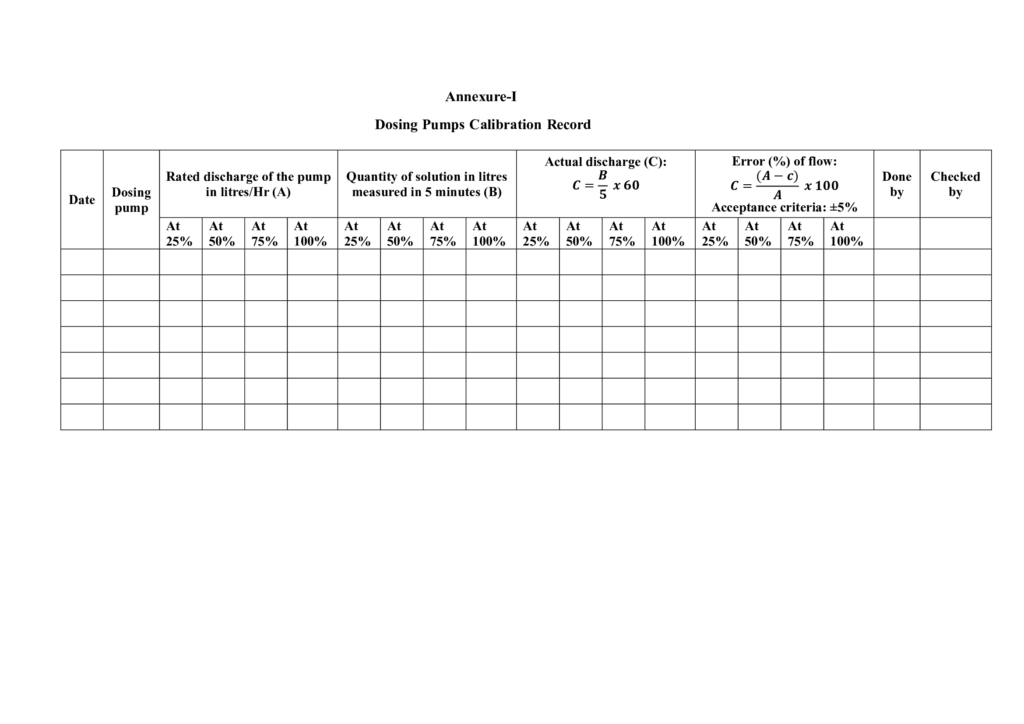

5.12 Note down the details as per the Annexure-I.

6.0 ABBREVIATIONS:

6.1 SOP – Standard Operating Procedure.

6.2 ENG — Engineering Department.

6.3 % – Percentage

7.0 REFERENCES:

8.0 ANNEXURES:

Annexure-I: Dosing Pumps Calibration Record